What are the specific characteristics of hardware stamping processing

2024-07-19()Views

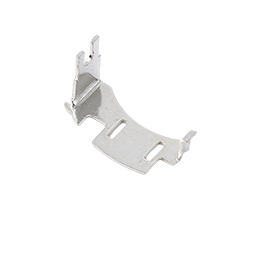

Stamping is a highly efficient production method, using composite dies, especially multi-station progressive dies, which can complete multiple stamping processes on a single press (single-station or multi-station), realizing fully automatic production from strip uncoiling, leveling, punching to forming and finishing. High production efficiency, good labor conditions, low production costs, generally can produce hundreds of pieces per minute. Compared with other methods of machining and plastic processing, press processing has many unique advantages in both technology and economy. The main performance is as follows.

1. The high productivity of stamping, and easy to operate, easy to realize mechanization and automation. This is because stamping is relying on the die and stamping equipment to complete the process, the number of ordinary press strokes per minute up to dozens of times, high-speed pressure per minute up to hundreds or even thousands of times above, and each stamping stroke may get a punch.

2. when stamping due to the mold to ensure that the size and shape of the stamped parts of the precision, and generally do not destroy the surface quality of the stamped parts, and mold life is generally longer, so the stamping of the quality of stable, interchangeable, with the “one and the same” characteristics.

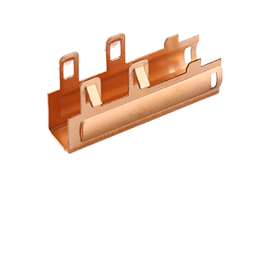

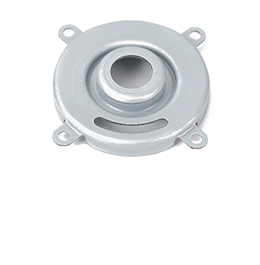

3. Stamping can be processed out of a larger size range, shape more complex parts, such as small to the stopwatch, large to the car longitudinal beams, cover parts, etc., coupled with the cold deformation of the material hardening effect of stamping, stamping of the strength and stiffness are higher.

4. Stamping generally does not generate chips and debris, less material consumption, and does not require other heating equipment, so it is a kind of material-saving, energy-saving processing methods, the cost of stamped parts is lower.

Latest News

-

An introduct...

Depending on the normal use of t...

-

Introduction...

1, JB/T7371-1994 “alkali pump me...

-

What effect ...

Electric vehicles are gradually ...

-

Do you know ...

The classification of motor part...

86 159-1379-7791

Cell phone:159-1379-7791(WeChat)

Telephone:0769-39029833

Email:huqihua@hjcmotor.com

Address:Room 101, Building F3, No. 215, Yuehai Avenue, Xiegang Town, Dongguan City, Guangdong Province, China